DOKA H20 BEAM

Doka timber formwork beams are the basis for many Doka formwork systems and have a wide range of uses.

Hundreds of thousands of these carefully manufactured beams do sterling service on countless construction sites every day. The H20 top and H20 eco beams are familiar names all over the world, and are the right choice for any application.

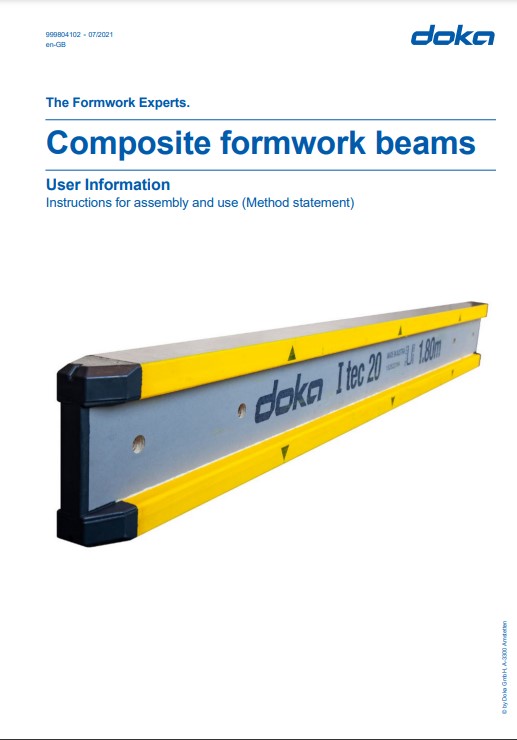

High load capacity

achieved by innovative composite technology:

permitted bending moment M = 9.0 kNm

allowed shear force Q = 20.0 kN

rigidity E x I = 640 kNm²

weight = 5.6 kg/lin.m

Save on equipment

thanks to optimized load capacity

up to one-third fewer floor props on timber-beam floor formwork Dokaflex 30 tec

up to 30 percent fewer form-tie points in wall areas Timberbeam formwork FF100 tec and Top 100 tec

50 percent fewer primary beams in the superstructures of fully loaded Load-bearing tower Staxo 40

More repeat uses

thanks to all-round protectionextra-long lifespan,

thanks to the proven 'top' beam-end reinforcementreduced close-out costs,

thanks to the I tec sheet that protects the entire length of the flanges

Composite formwork beam 20

(A) Top-beam-end reinforcement

(B) I single sheet

(C) Beams marked in 50-cm increment-grid

(D) System holes

(E) Notch for chalk line

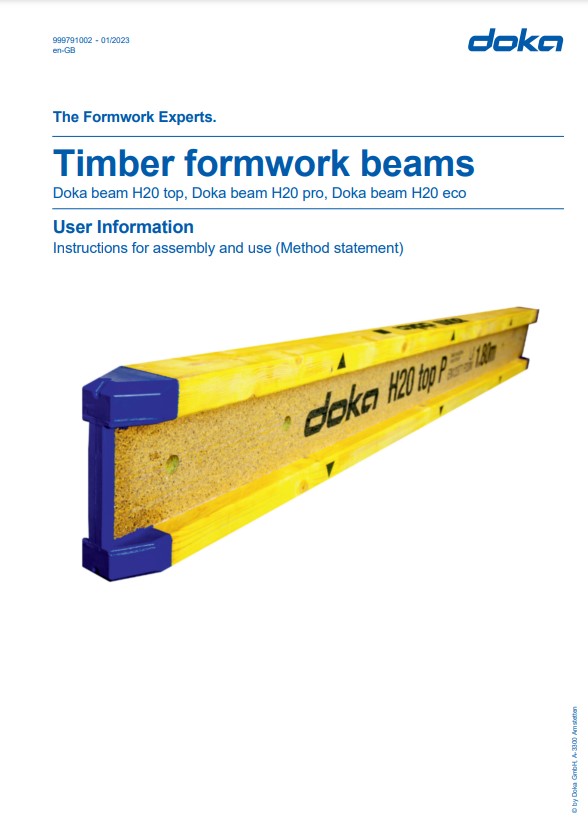

Timber formwork beam H20 top

Reduced damage at the end of the beam

Effective protection against moisture and UV radiation since ends are sealed around web.

Fast, safe formwork set-up with markings on the beam chords

(A) Top-beam-end reinforcement

(B) Web in versions N or P

(C) Beams marked in 50-cm increment-grid

(D) 2 system holes at each beam end

(E) Notch for chalk line

(F) Labeling belt width side; Optional: Customising possible

Timber formwork beam H20 eco

High-quality beam chords thanks to mechanical stress-grading

Less damage to beam-ends owing to bevelled flange-ends and beam rivets

Easy to handle

because of its very low weight

(A) End-reinforcement with bevelled beam-ends and extra plastic rivet

(B) Web in versions N or P

(C) Beams marked in 50-cm increment-grid

(D) 2 system holes at each beam end

(E) Labelling belt width side; Optional: Customising possible

About product

Moment (M) | 5 kNm |

Shear force (Q) | 11 kN |

Rigidity (E x J) | 450 kNm² |

Weight | 4.7 kg/lfm (N) | 5.3 kg/lfm (P) |

Certificate | EN 13377 |